Following our QuickRead on Categorising and Prioritising Ideas Part 1, we walked you through some…

ChangeWise QuickRead : Takt Time, Cycle Time and Lead Time

In order to create a Lean environment that is in harmony with customer demand, it is important to focus on the rate at which your product or service flows through the value stream. This is where Takt Time, Cycle Time and Lead Time come into play. In this QuickRead, we will take a look at each of these Lean metrics and explain what they are, along with how to measure them and the benefits they can bring to your organisation.

When should I use the Lean metrics?

If there is a customer with a demand, these metrics are relevant and beneficial, from car manufacturing to call centres, financial institutions to bakeries; they all serve customers who require a product or service.

For the purposes of keeping this Quick Read simple, we will refer to the service or product as a ‘widget’.

Let’s take a closer look at each metric in turn:

Takt Time

Takt Time is used to measure customer demand. It refers to the time between starting work on a widget and starting work on the next widget. It is the German word for ‘a precise interval of time’, and works like a metronome (the device used by musicians that marks time at a selected rate by giving a regular tick).

Think of Takt time as the “HEART BEAT” of the process based on the customer demand.

Remember! Takt Time must be defined properly or it can cause unnecessary employee stress and boredom. It is not ‘time and motion’ micro-management of employees akin to Taylorism, rather a study of process capability. On-going monitoring and continuous improvement are necessary to ensure this does not happen.

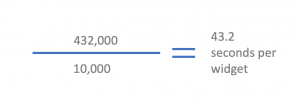

To work out your Takt Time, take your total available work time and divide it by customer demand:

For example:

- I have to make 10,000 widgets a month to meet customer demand

- My company has a 6 hour working day, 20 days a month

This equates to 120 hours a month which is 432,000 seconds

To meet customer demand, we need to produce one widget every 43.2 seconds.

People often misunderstand Takt Time, assuming they need to work out how long their process takes to make a single item, then multiply this number by the customer demand. This number is then used to work out how many employees they will need to match the demand – this calculation will ultimately assume more people are required to fulfil customer orders. However, Takt Time encourages us to think the opposite. It encourages us to redesign our process/operations to match customer demand using the resource available (available time/output capacity). It should be a big driver of continuous improvement activities.

Remember! If we were doing this in a live Lean operation, we would also consider the likelihood of timing delays due to operational issues, downtime, breaks, staff absence etc. So, in reality, the Takt Time would be less than 43.2 seconds. A future QuickRead will explain how to address some of these issues to using OEE (Overall Equipment Effectiveness).

Cycle Time

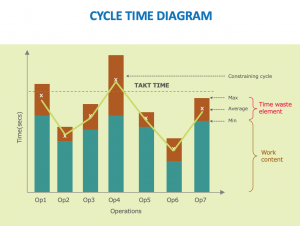

This is the average time it takes to complete one unit or step in the process. Understanding the Cycle Time is important, as it will identify constraining cycles that could potentially impact our ability to meet demand. In the example below, Op 4 is the constraining cycle, as it is longer than our required Takt Time.

It is also important to record any Cycle Time variation, i.e. the large difference between operation 4 and 6, as this will help to identify waste and opportunities to rebalance the line.

Remember! Takt Time signifies the required rate of production whereas Cycle Time is the actual time taken for individual steps of production.

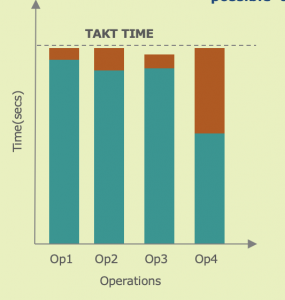

Rebalancing the Line

In order to meet demand and ensure efficiency, the aim is to process the widget as close to the Takt Time as possible. There are various actions we can take to achieve this including, removing some of the waste in each cycle, creating fewer operations by moving employees around, simplifying, eliminating or combining steps, cross-training employees and cellular working. Many processes are also set up to run sequentially, so moving to parallel processing can make huge gains in process capacity.

Lead Time

This refers to the total time taken from order to delivery to the customer. This is really important because it tells you how long your customer has to wait for a product or service, allowing you to benchmark yourself against competitors and work on improving your customer experience.

You can record Lead Times by Walking the Gemba and creating Value Stream Maps (see our ChangeWise Quick Reads for more information on these topics).

Understanding Lead Time is essential for helping us to look at ways of removing non-value add steps/waste and helps to optimise the process for improved output.

If your Lead Time exceeds your Cycle Time, you will likely have a lot of unnecessary inventory in your system. In contrast, if your Cycle Time exceeds your Lead Time, you will risk meeting customer demand.

What are the benefits of understanding these Lean Metrics?

Understanding these metrics will:

- Improve customer demand

- Create effective resource management

- Identify which steps are causing bottlenecks/constraints

- Help to streamline and optimise the business creating efficient output.

- Allow efficient time management of tasks

- Increase productivity

- Reduce the impact of unplanned downtime due to process clarity

- Assist in the provision of accurate widget delivery estimates for customers

Remember! If customer demand goes up, you can recalculate your Takt Time to help meet new demand, or switch on more capacity by opening another cell.

In Summary

Takt Time is the German word for ‘a precise interval of time’. It is used to calculate customer demand. Cycle Time is the average time it takes to complete one unit or step in the process, and Lead Time refers to the total time taken from order to delivery to the customer.

These metrics work together to help you identify efficiency issues that can impact customer demand. Understanding and monitoring these metrics will ultimately improve your bottom line.

Want to know more about how these Lean metrics could help improve your competitive advantage? Contact us at info@changewise.co.uk

ChangeWise believes employee engagement is the foundation for successful Change. Training and coaching your people to use simple continuous improvement techniques will enable your organisation to continuously adapt and stay ahead in a constantly changing and challenging environment.

For updates and interesting Lean Change insights, connect with us on LinkedIn.

Find out more about our Public Training Courses