To complement our series of QuickReads covering measurement, we will now explore the various data…

ChangeWise Quick Read: Measurement Series: Measurement Categories

As we continue our series of helpful articles on measurement, we take a quick look at the different measurement categories you might like to consider before creating a Data Collection Plan. We will cover what these categories might include and why they are important.

As always, it wouldn’t be possible to talk about data without mentioning W. Edwards Deming, so we’ll be sure to throw a few of his famous quotes in as we go!

🏆 Top Tip! If you’re feeling super keen, you might like to look at the following Quick Reads before reading further:

Clarifying Customer Requirements CTQs

Before we start, who was Deming?

Deming was one of the founding fathers of Total Quality Management (the revolution in Japanese manufacturing management in the 70s/80s). Deming used statistical methods to quantify manufacturing processes, emphasising the importance of data measurement and analysis in business. His well-known quote “In God we trust. All others must bring data” (sorry, couldn’t help it – had to get that classic one in!) highlights the leverage quality data can bring to the table.

But why are measurement categories important?

Because companies love collecting data………whenever we visit a new client they typically have a wealth of reports and data that have been carefully collated and artistically scribed in beautiful calligraphy (usually requiring several hours of labour and some hardcore excel skills)……so it’s really tough when we have to fess-up and tell our clients that the data they have isn’t really relevant or driven by customer value.

Companies must ask themselves how the data is helping to drive their vision and customer needs.

Another sound reason to consider measurement categories is often because the root cause of the process issue is unknown and an analytical review is necessary. For example, a shipping company might have a large number of late parcels being shipped – yet there is no obvious reason for the delay based on the existing data. Additionally, there are lots of clients who simply don’t have the data readily available for analysis.

Sailing onwards without succinct, value-add measures may steer you in the wrong direction or result in unnecessary analysis that will add cost and time later. Prioritising your data measures upfront will ensure the project team and all those impacted by the improvements, are working towards a common goal.

Photo by Kelly Sikkema on Unsplash

Ok I get it! Tell me about Measurement Categories please!

Of course! The data must encompass the metrics you aim to improve so we suggest considering the five measurement categories below:

1: Financial (Cost/Income)

Before starting any Lean Six Sigma project, it is critical you consider the hard benefits you want to deliver. This can include a myriad of savings, so be sure to challenge your thinking on this or you could miss key benefits – if you can’t measure it, you can’t improve it!

Think about: What do we cost? What resources do we use? How much profit/surplus so we create?

Some examples might be overtime, cost of rehiring, reduced compensation, increased sales, reduction in machinery maintenance costs, reduction in stock volume required, supplier leverage, reduction in labour costs.

🏆 Top Tip! When looking for hard benefits, we recommend thinking about how you make, spend and lose money within your operation. If you can add something in one of these 3 categories, you can put a hard benefit against it – and measure it!

2: Quality

Are you delivering value to the customer and what quality measures are fundamental to the success of your Lean improvement? Consider these from your customer’s perspective (internal and external). They might include reduction in errors, reduction in overprocessing, reduction in health & safety incidents, Right First Time (RFT) volume, Overall Equipment Effectiveness (OEE).

What does quality mean to your customer? If you don’t know…….go and find out!

3: Time/Delivery

What are your service and delivery levels? Are they really driven by customer value? Many companies have SLAs set internally without customer input. This usually leads to two scenarios:

1: Dissatisfaction because timings are unacceptably too long but the SLA suits the pace at which an operation can process work.

2: Situations where the customer does not actually require something within the set SLA and would be happy to wait – yet they are often still dissatisfied by quality as a result of employees working so hard to process work within unreasonable timings.

Really think about how lead-times impact customer satisfaction, failure demand and profits within the operation. Our article looking at Takt Time, Cycle Time and Lead Time might help with this.

4: Customer Value

Customer Value can be defined as how much a product or service is worth to a customer. Once you understand this, you will need to find a way to measure any improvement. This might be looking at increased loyalty and customer retention, lower cost to serve, higher recommendation rates, increased customer satisfaction scores or complaint reductions. Whatever you measure, make sure it’s driven by the customer 👑

5: Staff Morale & Safety

How safe are your staff, products and services (health, safety, environmental and risk)? What measures would reflect these improvements? Successful Lean initiatives act to increase employee satisfaction and create a cohesive, improved working environment. Identifying the measures here might include; reduced staff turnover, increased employee satisfaction scores, reduced health & safety incidents, reduced absenteeism.

🏆 Top Tip! As always, measurement categories are best discussed as a team. Always include subject matter experts who are close to the process on a regular basis.

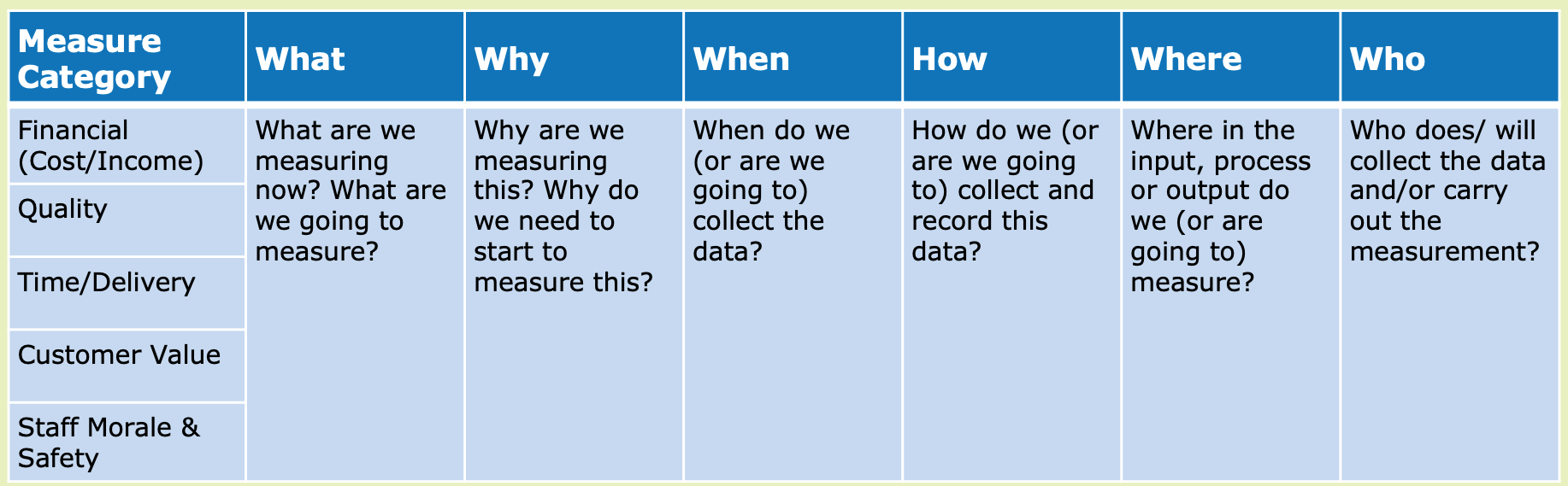

Once you have a better understanding of what needs to be measured. You might like to use the 5W + 1H technique to create a practical plan for collecting and measuring the improvements:

The next step is to develop your practical strategy for measuring the data in each category. This is where the Data Collection Plan comes in – but we’ll save that for next time!

In Summary

Considering Measurement Categories ensures that the project team are collecting value-add data that will ultimately drive their company vision and deliver customer needs. It will help to clarify the root cause of any process issues and provide information where the data is not currently available for analysis. Failing to complete this step may result in unnecessary investigations that will add cost and time later.

Want to know more? Get in touch with the ChangeWise team at info@changewise.co.uk

ChangeWise believes employee engagement is the foundation for successful Change. Training and coaching your people to use simple continuous improvement techniques will enable your organisation to continuously adapt and stay ahead in a constantly changing and challenging environment.

For updates and interesting Lean Change insights, connect with us on LinkedIn.