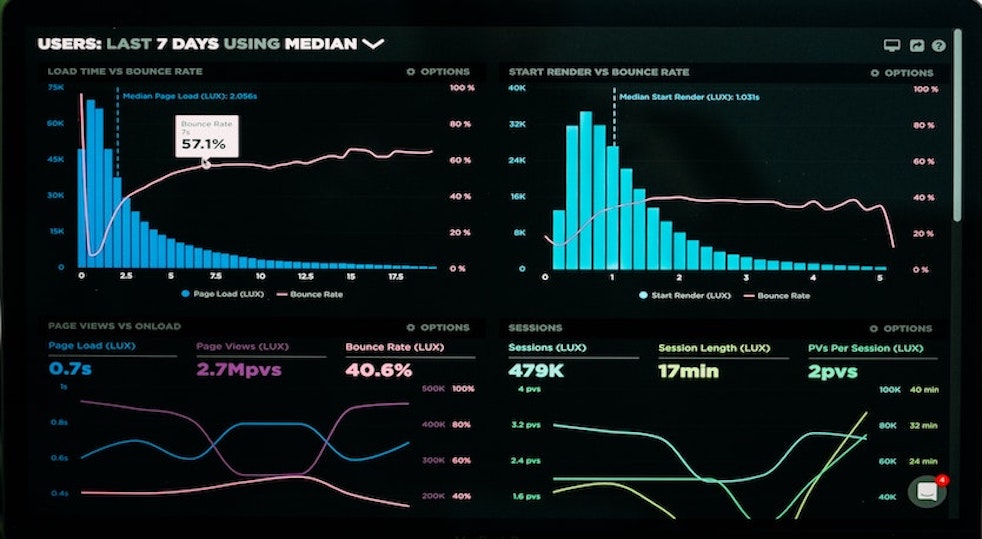

To complement our series of QuickReads covering measurement, we will now explore the various data…

ChangeWise Quick Read: 5 Principles of Lean Part 2/5 Identify the Value Stream.

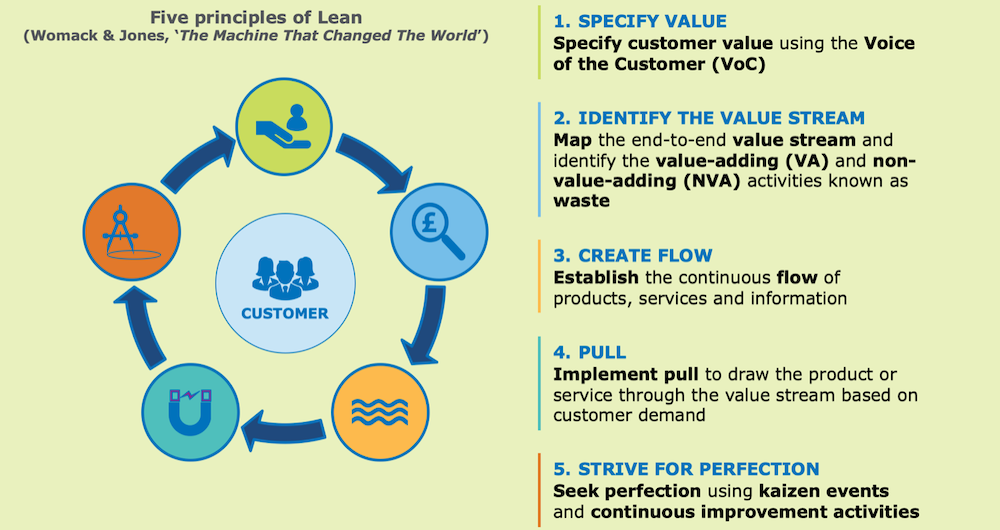

In our previous Quick Read, we looked at the first Lean Principle Specify Value, including what this means in a Lean organisation, how to challenge your thinking regarding what your customers want and need from your products and services, along with some useful tools and techniques to help.

Once you have a better understanding of what constitutes value, you can move onto Principle 2: Identify the Value Stream

What is a Value Stream?

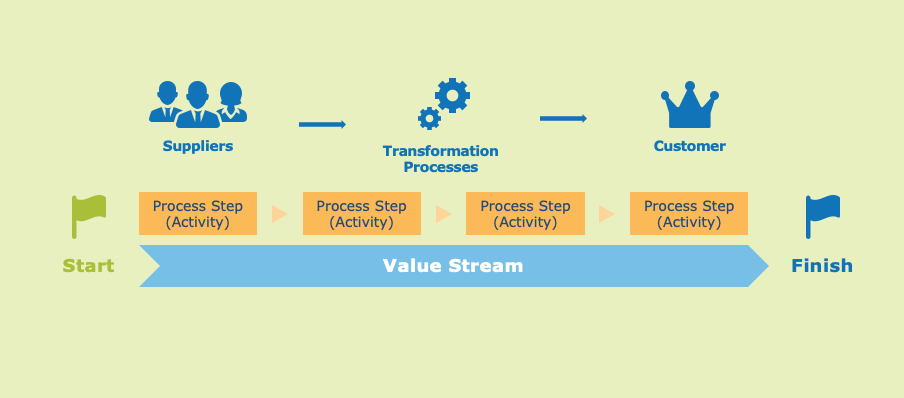

The Value Stream is the end-to-end (E2E) sequence of steps taken to create customer value. Simply put, it shows how something is turned into something else.

Rather than thinking of organisations in the traditional silo model with functions (Marketing, HR, IT, Finance etc,) it focuses on where the customer enters the process, all that happened in-between and finally, where they exit.

Thanks, but I’ve done process mapping before….

Whilst process mapping is important, value stream mapping is quite different because it represents how things really work as opposed to how they should work. This means the value stream also captures everything that is non-value add in our process.

So, Lean organisations are organised around value streams rather than functions?

Exactly! And this type of Lean business model offers substantial benefits to your organisation. Once you understand where your value steam starts and stops, you can:

- Use visualisation to better understand your business processes and how they are connected

- Identify which process steps add value

- Identify which process steps produce waste

- Create continuous flow

- Create a process for, and identify continuous improvement opportunities

I’m in! Tell me how I create a Value Stream Map!

No problem! Just remember this is a high-level overview, so please pop over to our Quick Read on Value Stream Mapping for more details if you’re in need of more information.

Step 1: Determine the scope of your Value Stream

Where does your value stream start and stop? We like to use a SIPOC to visualise this (Supplier, Input, Process, Output and Customer).

Step 2: Select the Value Stream Team

This should consist of people who use the process, typically not managers or your leadership team. This is because you are looking to map the ‘as is’ and not how a process should work.

Step 3: Walk the process

Think about how your product or service flows through the organisation and ‘walk the process’ (sometimes known as Gemba walking). This hugely valuable activity means visiting the sites where the process is used – almost as if you are the product or service travelling through the process.

⚠️ Important Point!! We strongly recommend that the VSM team walk the process together. This is a great way for subject matter experts to see first-hand how their operation impacts the value stream up/down stream. It also helps to build a value stream culture and remove silo thinking.

Step 4: Map the Value Stream

Value Stream Maps can be created in several ways using various mediums. However, we prefer to create them using a roll of brown paper on the wall. Having a large, visual representation really brings home the complexity of an organisation and makes it easier to demonstrate opportunities when talking with stakeholders and senior leadership teams.

Step 5: Identify the Value

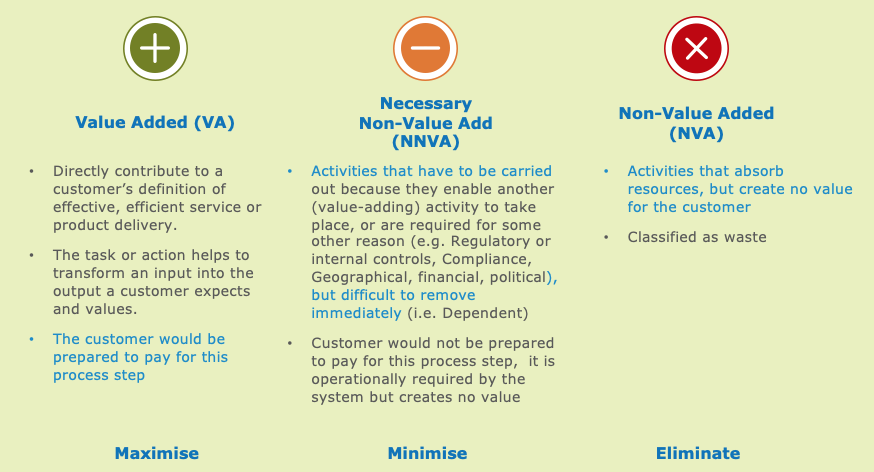

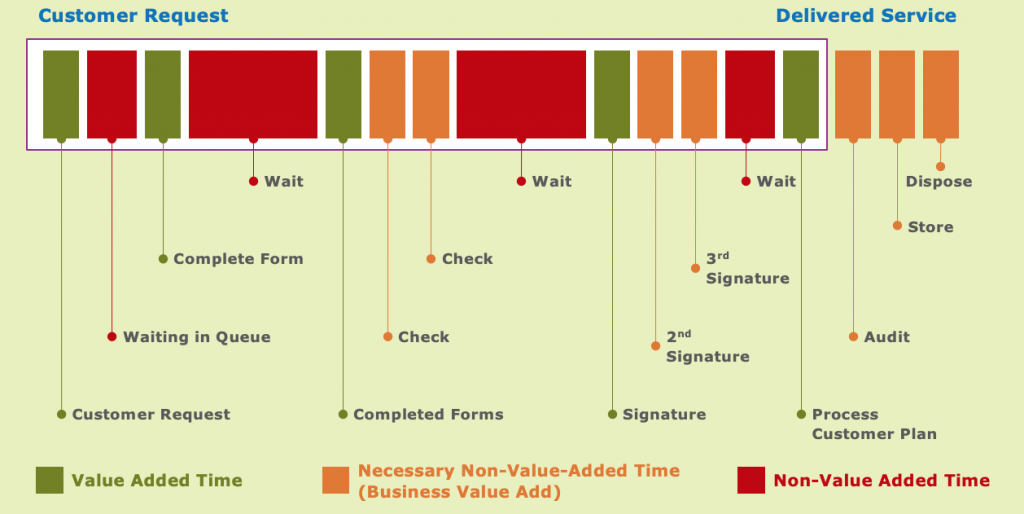

Assess each process step and categorise as follows:

⚠️ Remember!! Value should always be assessed through the voice of the customer (Principle 1).

Teams should not be surprised to find that only 15% of their overall process truly adds value. The example below shows the process for a customer reporting an issue at a call centre:

Without value stream maps we miss the fact that there are a lot of steps/actions a customer must take to do business with us. Understanding these parts of the process is where we will find excellent opportunities to continually improve, delight our customers and gain their loyalty.

In Summary

Lean Principle No. 2 is Map the Value Stream. This principle helps us to understand the physical flow of material and information in our process. It represents the actual process and not how the process should work, which in turn enables teams to identify and remove/reduce waste. The result is increased productivity, reduced cost and higher levels of customer satisfaction.

Want to know more? Get in touch with the ChangeWise team at info@changewise.co.uk

ChangeWise believes employee engagement is the foundation for successful Change. Training and coaching your people to use simple continuous improvement techniques will enable your organisation to continuously adapt and stay ahead in a constantly changing and challenging environment.

For updates and interesting Lean Change insights, connect with us on LinkedIn.