To complement our series of QuickReads covering measurement, we will now explore Failure Demand (FD).…

ChangeWise Quick Reads: Value Stream Mapping

What is a Value Stream Map?

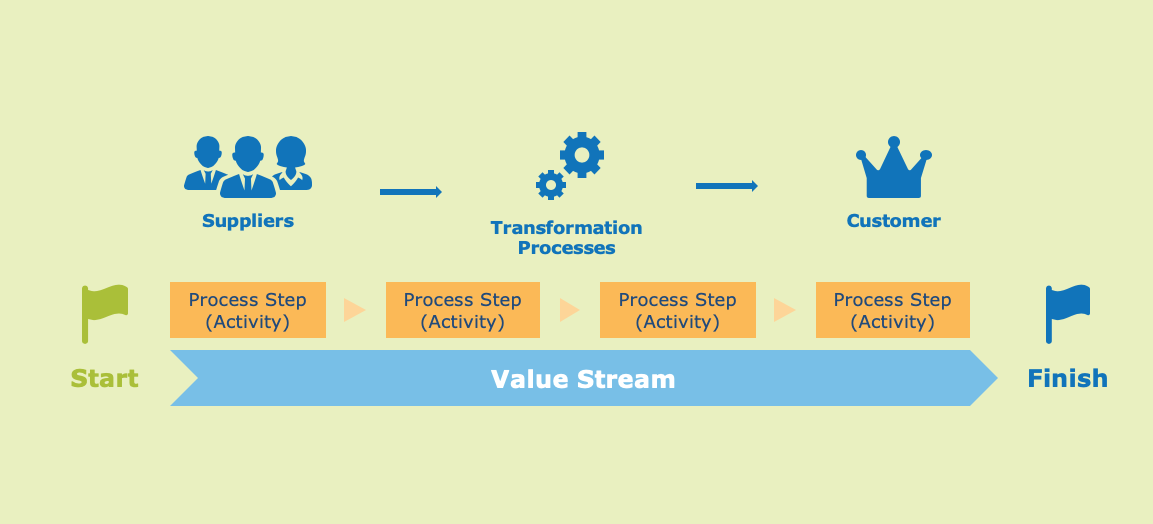

The Value Stream Map (VSM), refers to the series of steps that occur in your business process to provide the product, service and/or experience the customer desires. It is an important tool used within Lean Continuous Improvement to document, analyse and improve the flow of information or services required to produce a product or service for a customer.

Remember! A customer refers to both internal and external users of your services/products, so it is likely organisations will have several value streams.

Why use a Value Stream Map?

Organising your business around value streams offers substantial benefits to the organisation. Once you understand where your value steam starts and stops, you can:

- Use visualisation to better understand your business processes and how they are connected

- Identify which process steps add value

- Identify which process steps produce waste

- Create continuous flow

- Create a process for, and identify continuous improvement opportunities

How do I create a Value Stream Map?

Step 1: Determine the scope of your VSM. You need to understand where your value stream starts and stops. I like to use a SIPOC to visualise the ‘helicopter view’ (Supplier, Input, Process, Output and Customer).

Step 2: Select the Value Stream Team. This should be people who use the process, typically not operational managers or your leadership team. It is vitally important you map the ‘as is’ and not how a process should work.

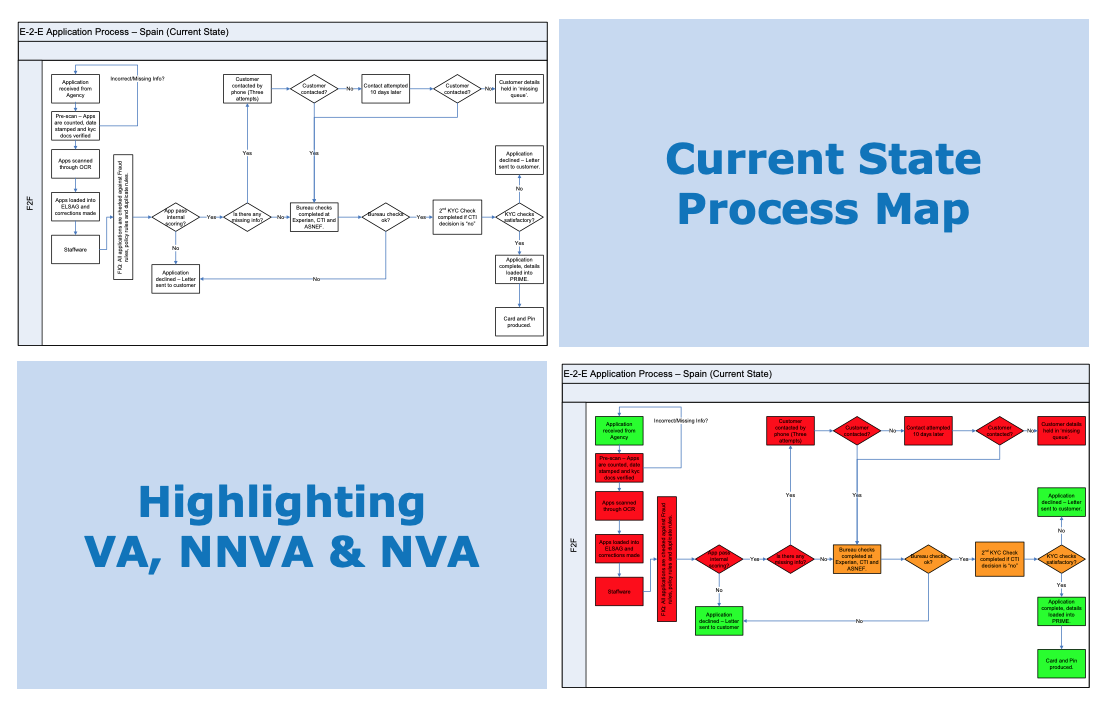

Step 3: Think about how your product or service flows through the organisation and map each step. An excellent way to do this is to ‘walk the process’ (sometimes known as Gemba walking), this hugely valuable activity means visiting the sites where the process is used. I strongly recommend that the VSM team walk the process together.

Step 4: Map the Value Stream. VSM’s can be created in several ways using various mediums. However, I prefer to create mine using a role of brown paper on the wall. I find this large, visual representation really brings home the complexity of an organisation and makes it easier to demonstrate opportunities when talking with stakeholders and senior leadership teams.

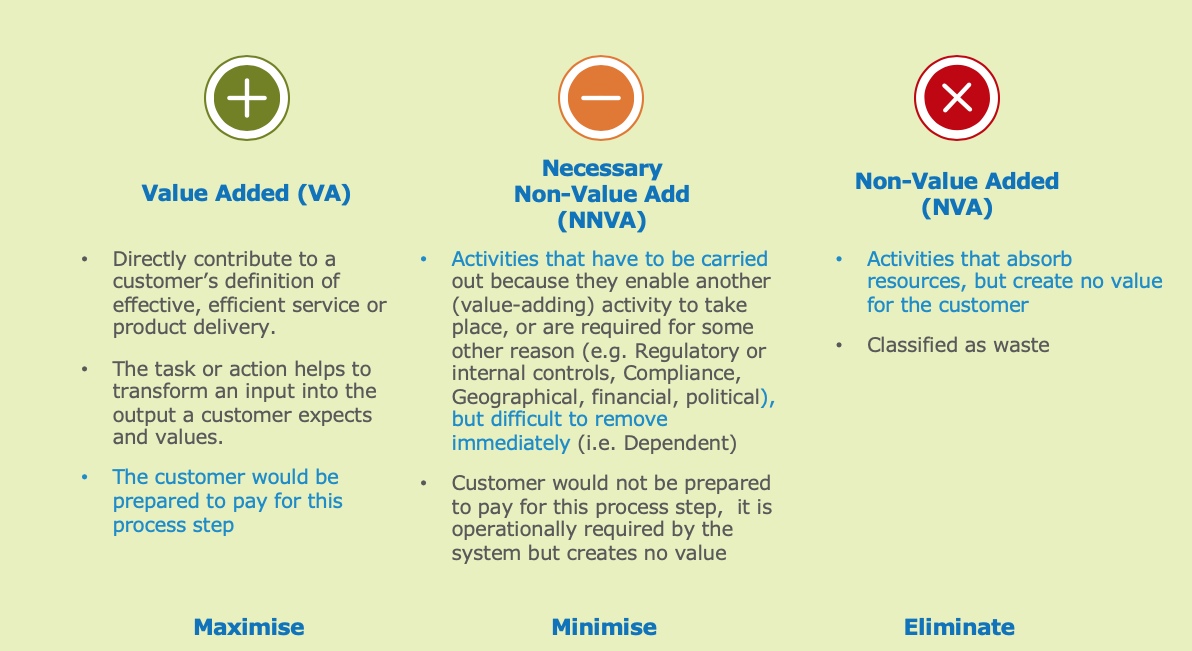

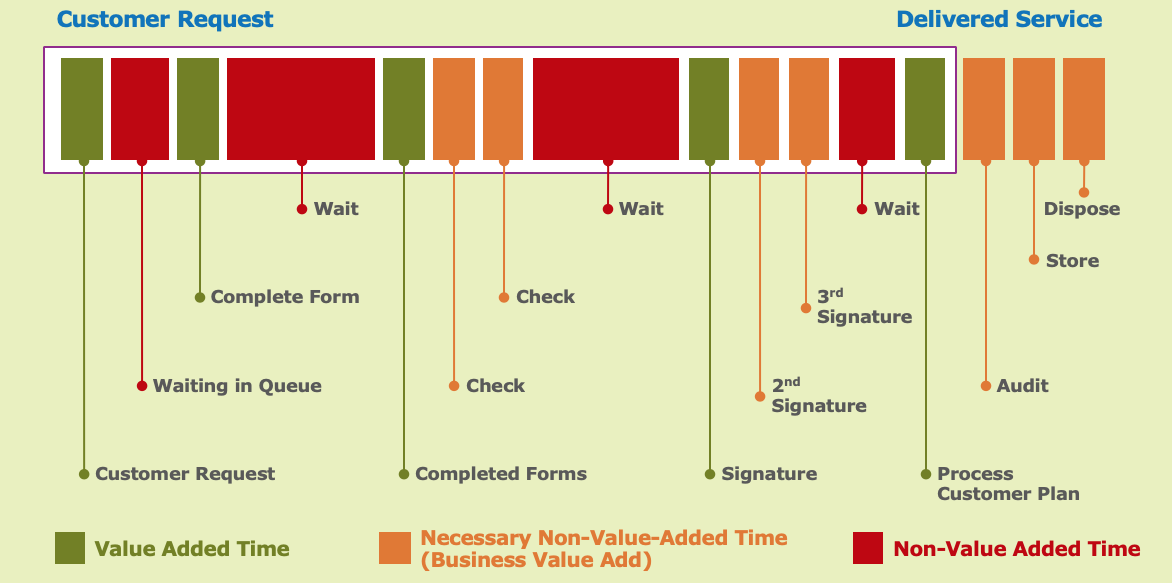

Step 5: Identify value through assessing each process step and categorising as follows:

Remember! The customer is king. You must always try to assess Value from their perspective.

Step 5: Plan your Future State through removing NVA steps.

In Summary:

Value Stream Mapping is critical in providing leaders, stakeholders and team members with a holistic view of their organisation and where opportunities exists to create value, gain competitive advantage and improve service to customers. Through the simple elimination of NVA steps, many quick wins and benefits can be achieved.

Want to know more? contact us at info@changewise.co.uk

ChangeWise believes employee engagement is the foundation for successful Change. Training and coaching your people to use simple continuous improvement techniques will enable your organisation to continuously adapt and stay ahead in a constantly changing and challenging environment.

For industry updates and interesting Lean Change insights, connect with us on LinkedIn.

Find out more about our Public Training Courses