To complement our series of QuickReads covering measurement, we will now explore Failure Demand (FD).…

ChangeWise Quick Read: Introduction to Kanban

In this Quick Read, we take a high-level look at Kanban. We explore where it comes from, what it is and the benefits of implementing.

Where did Kanban originate?

Kanban is a scheduling system for lean /just-in-time manufacturing, it means ‘Sign Board’ in Japanese. Taiichi Ohno, an industrial engineer at Toyota, developed Kanban to improve manufacturing efficiency. Kanban is one method to achieve ‘Just In Time (JIT)’.

What is Kanban?

Kanban is a visual management tool for any work that follows a process. It imposes limits on the length of time a work item can stay in a process step at any given time – we call these Work In Progress (WIP) limits. When a work item stays in a process step for too long, a visual cue is triggered to warn the team. These visual cues also tell us how much to produce and when.

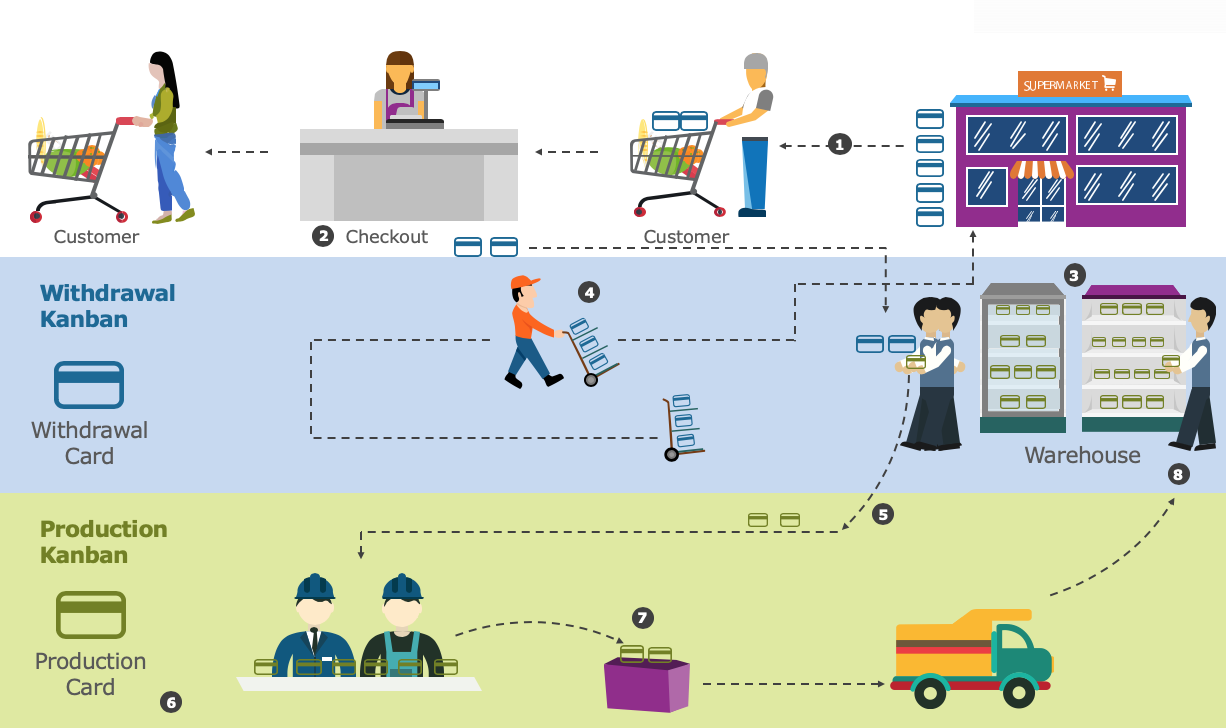

In Just-in-Time production control systems, a Kanban card is used as the pull signal to replenish parts to the active operation.

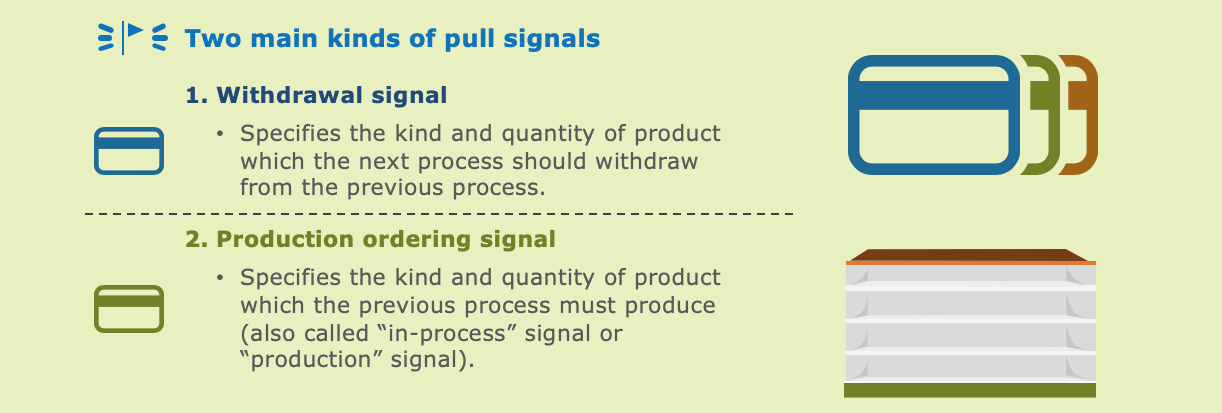

There are two main types of pull signals:

A supermarket is an inventory at the end of a pull system that stores items sorted by their part types in a first-in-first-out sequence. Whenever a part leaves the supermarket, a signal for reproduction is sent back to the production system:

Although Kanban originates from manufacturing, it can be applied to many different organisations and sectors to improve processing, including maintenance and equipment, critical spares management, stationery replenishment, laboratory testing analysis, parts replenishment, production support, software development and several customer service operations.

What are the benefits of a Kanban System?

Kanban helps to keep work flowing through the business process, ensuring a steady flow (to a Takt time) of tasks that are always 100% complete. This improves flow, reduces lead time and inventory costs, delivers value quicker to customers, and increases quality and predictability.

By limiting the WIP, encouraging multi-tasking and ensuring activities are 100% complete before starting anything new, organisations can benefit from improved resourcing.

In Summary

Kanban is a visual system for managing work as it moves through a process. The goal of Kanban is to minimise inventory costs, identify potential bottlenecks and ensure a smooth flow of work from start to completion in order to drive a leaner and more agile organisation.

Want to know more about implementing Kanban in your organisation? Contact us at info@changewise.co.uk

ChangeWise believes employee engagement is the foundation for successful Change. Training and coaching your people to use simple continuous improvement techniques will enable your organisation to continuously adapt and stay ahead in a constantly changing and challenging environment.

For updates and interesting Lean Change insights, connect with us on LinkedIn.

Find out more about our Public Training Courses